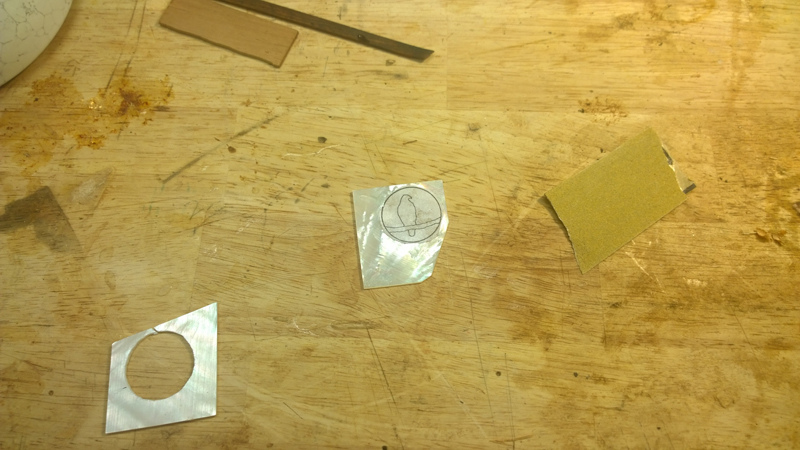

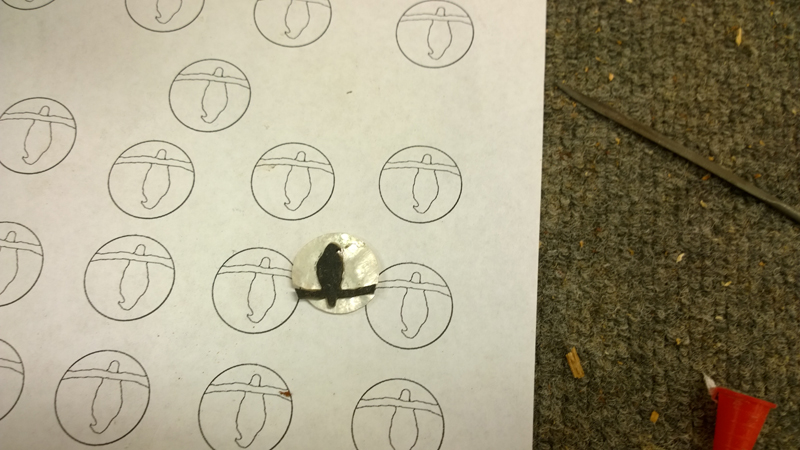

Well I am getting closer; I glued up a stack of veneer and white and black fiber for the head stock. I pressed it in one operation using LMI white glue. The book suggested epoxy, but given that this was fiber sheets I did not think that it would be relatively stable with the moisture in the glue. The glued up stack did not warp.

I made a 15% wedge and planed the nut side of the veneer.

Before gluing on the head stock veneer I made triply sure that I had the fret board clamped in the right angle as I used the fret board, and a brass bar to position the head stock veneer. Then I glued it on with a bunch of clamps.

I roughly cut the headstock shape out with my band saw and used my safe_T planer to get the head stock thickness close.

I have had the fret board stuck to the neck with a couple of pieces of double sided tape. To finish the bolt on extension I need to remove the fret board. Before doing so I drilled four 1/32" alignment pin holes through a couple of fret slots into the neck. Not so deep that they will come out the other side when I shape the neck.

The book called out T-nuts but as my extension was not quite centered I would have been very tight on the treble side to mount the T-nuts. I used brass inserts instead. I had the extension clamped to help avoid blowing out the side when screwing in the inserts.

Now I with everything ready to glue on the fretboard I placed a couple of dabs of silicon on under the truss rod, tested my fret board alignment again, and then glued the fret board on with a fret board caul that puts pressure on the edges of the fret board.

Should look like a guitar by the end of the week!