ozziebluesman wrote:Tim, I just finished bending some concert ukulele sides out of sapele. I had no cracking problem and used an electric bending iron. It is my first time bending sapele and i noticed much less spring back than indian rosewood. Side thickness was a tad under 2mm thick.

Cheers

Alan

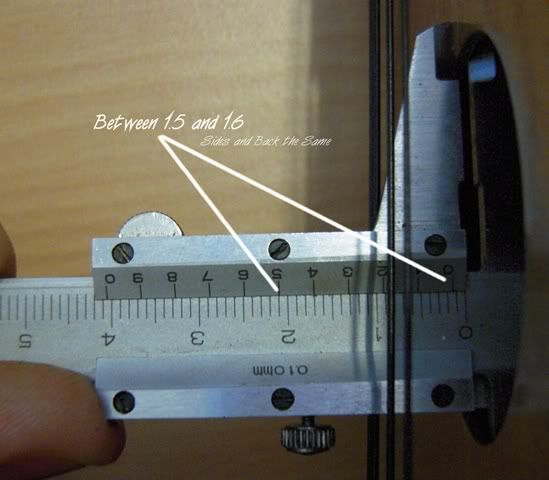

That would be my problem to thicker timber I was trying to bend 2.4 but i thought anything under that maybe to thin. What is the optimum side, back and sound board thickness? What does your electric bending iron look like?

guitarcam wrote:Tim, what timbers was this uke made from?

Walnut veneer sides

sepele veneer back and sound board

Pine braces and sepele neck and toe blocks

Birds eye maple bind

sepele neck

Wenge finger board and saddle

white corian bridge and nut.

It sounds good but i think the sound hole is to small and is a little quite. It much nicer to play than my $30 mahalo

Regards