Thicknessing by hand

Thicknessing by hand

This is a question for everyone especially Martin. Been throwing around the idea of buying myself a perfomax drum sander and a suitable dust extractor to go with it. Trouble is, it is a shit load of money for something that I will only use to thickness the top, back and sides then will sit there while i build the rest of the guitar. My idea while not being original is to thickness by hand. Inspired by Martins "score" thread I was wondering if a good quality scraper plane and smoothing plane could do the job. I know it would take a lot longer - but time I have plenty of, not so much money though. I came up with two planes the Veritas scraper plane and to copy Martin the Lie Nelson smoothing plane and the toothed blade. Would these be suitable to thickness the back, top and sides any opinions would be greatley appreciated. I know they're not cheap but they are not as expensive as the drum sander and dust extractor. Are these two planes a good choice or is there something better?

Carpe Diem

My mind often wonders onto drum sanders and it would be nice to be able to shove a back through same and have it magically come out the other side at final thickness. If I was making guitars for a living where time is money Id definitely say get one. However I dont build for loot and I love working with planes and cabinet scrapers so a drum sander is low on the list of things to buy.

I have a fairly impresive fleet of planes and scraper planes but to tell the truth only a few of these tools get regular use. My most used planes are as follows:

1. Veritas Low angle block plane (not used for thicknessing but used for just about everything else)

2. Miller Falls scraper plane. I have a Veritas scraper plane in my arsenal but the Miller Falls is my preferred weapon.....it's blade is easier to dress than the Veritas.

3. Veritas No 4 smoother. A nice plane and it would even nicer if Veritas offered a toothed blade option for the tool (they do for the LA equivalent).

Given a choice of a LN No 4 plane or Veritas scraper plane I'd probably go for the LN but only because LN make a toothed blade for the thing (an extra $125).

Once youve rough worked your top/back/side set with your plane youll then need to do the final working to final thickness using cabinet scrapers. These nifty hand tools are one of the best tools ever invented. Working an edge into a cab scraper can take a bit of time to get down pat but its worth the effort.

Cheers Martin

I have a fairly impresive fleet of planes and scraper planes but to tell the truth only a few of these tools get regular use. My most used planes are as follows:

1. Veritas Low angle block plane (not used for thicknessing but used for just about everything else)

2. Miller Falls scraper plane. I have a Veritas scraper plane in my arsenal but the Miller Falls is my preferred weapon.....it's blade is easier to dress than the Veritas.

3. Veritas No 4 smoother. A nice plane and it would even nicer if Veritas offered a toothed blade option for the tool (they do for the LA equivalent).

Given a choice of a LN No 4 plane or Veritas scraper plane I'd probably go for the LN but only because LN make a toothed blade for the thing (an extra $125).

Once youve rough worked your top/back/side set with your plane youll then need to do the final working to final thickness using cabinet scrapers. These nifty hand tools are one of the best tools ever invented. Working an edge into a cab scraper can take a bit of time to get down pat but its worth the effort.

Cheers Martin

Thank you mate I already got the cab scraper sharpening under control and also love working with planes, that is why I think this is a good option. I aiready have a veritas block plane and I use the crap out of it so if the veritas scraper plane is as good I will be happy. I have never used a scraper plane so hopefully I will be able to dress the blade. Thanks again.

Carpe Diem

The first thing I do with a scraper plane blade is work a curve into end of same. Even though the Veritas scraper plane has a screw to put a flex in the blade youll still get the edges of the blade gouging into the wood. My honing guide isnt wide enough to take a scraper plane blade so I work in a 45 degree bevel on the thing by hand on a Japanese water stone before working the burr into same.

- Mark McLean

- Blackwood

- Posts: 1124

- Joined: Thu Apr 10, 2008 2:03 pm

- Location: Sydney

The Wagner Safe-T-planer is a very cost effective (<$50) way of getting backs, sides and soundboards close to final thickness, then you complete the job with a cabinet scraper. It is very easy to use if you have a drill press, faster and less effort than hand planing, and minimal risk of tearout on your expensive tonewood. Another advantage is that it doesn't make fine dust that you end up choking on, but it does chuck little bits of chipped wood all over your bench and floor.

Hey Martin I just got scared the veritas scraper plane is not impossible to sharpen is it. I dont want it to be one of those barsted jobs that I will never do. At the moment I sharpen all my planes and chisels with a honing jig and a few different grade stones it is one job that I have to say I really enjoy.I am definatly going the Lie Neilson just not sold on the veritas scraper yet.

Carpe Diem

- J.F. Custom

- Blackwood

- Posts: 779

- Joined: Fri May 01, 2009 9:13 pm

- Location: Brisbane

- Contact:

Well, here is my opinion.

I've got both planes (though not as many as I'd like) and the drum sander/dust extractor combo.

I have to agree with Martin here. In a sense, they are two different approaches and philosophies if you like. The machine will certainly do a good job very quickly. You will however lose the enjoyment of the 'feel' of working the timber. There is more satisfaction in hand planing and scraping to your desired finish than that felt when the timber feeds out the back end of the drum sander!

Drum sanders are great for speed and also for 'difficult' timbers such as anything highly figured. An electric planer/thicknesser will rip the guts out of figured material or at least the risk is high so if it were between these, you'd go the sander. Some hand planes however are also made to deal with difficult and cranky timbers and though care must be taken and skill required, will do an excellent job. Drum sanders are somewhat 'no brainers'. They are a work horse to get you from A to B very quickly.

As you are probably aware, you definitely need a dust extractor on a drum sander. This does make the equation quite expensive. Having said that, the planes you are looking at are not cheap either! They will however hold their value over time being quality tools.

Shit I ramble.

Right thats it, things to consider -

Hand planes: will work and do a good job, even quite quickly however learning curve is steep and stakes are often high. Tearing a chunk from your figured blackwood back at 2.5mm thick is not a pleasant experience, should you have thought otherwise. They are quiet - use anytime! They create lovely shavings not nostril clogging dust. You can precisely control what thickness your results are but getting that thickness evenly across the board takes practice. Veritas make some lovely planes. I'm with Martin - I have the low angle block and it's great, in my opinion, better than the LN of same but again, not for this job. I have tried the Lie-Neilson scraper plane which works beautifully. I'm sure as does the Veritas. Both companies manufacture excellent hand planes and which one I would choose over the other depends on the model itself. As for the smoother, you could go either way and be very happy. Veritas do make low angle versions of several of their planes which are beautiful to use and also slightly wider than standard. In essence, the combo you mention will work fine, as would the reverse combo (with say a Veritas low angle smoother or bevel up smoother) which is the way I'd personally lean. Another option, which I have, is a Terry Gordon smoother (http://www.hntgordon.com.au). These are traditional wooden planes made here in Australia that are of such a design as to be both smoother and scraper in one (by reversing the set-up). They work beautifully on even highly figured hard woods, but don't have the ease of micro-adjustment which puts some people off. The blades are awesome and he does have a newer mechanically adjustable model for those who don't like the hammer technique. Just a thought but highly recommended.

Drum Sander: The Performax sanders are made well and work well but as with all machines, need to be used within their capabilities and also require maintenance. They are not 'thicknessers' but finish sanders and as such, they will only remove a small amount of material at a time. This is mostly what you want but if you try to take too much, the smaller units will stall quickly which frustrates many and causes people to think they are faulty. So taking a 5mm chunk of Indian Rosewood down to 2.5mm can take many passes and some time. They aren't the nosiest machines in the workshop but still cause a racket. Adjusting them should your material be coming out uneven can be a pain in the **** depending on model. Having said all this, I wouldn't be without mine now. There are jobs I still reach for my hand planes for but for the general thicknessing down to size of my plates, I use the sander every time. You can control very well the thickness achieved though I still prefer to finish with scrapers. Note also that many models will not sand down to the thickness we require as they limit this so you do not sand into your conveyor plate or belt. You would need to build a 'sled' to carry your plates.

Oh and I agree again with Martin - go buy some scrapers and practice using them. They are the most useful bits of metal in the workshop!

Hope this helps.

Jeremy.

I've got both planes (though not as many as I'd like) and the drum sander/dust extractor combo.

I have to agree with Martin here. In a sense, they are two different approaches and philosophies if you like. The machine will certainly do a good job very quickly. You will however lose the enjoyment of the 'feel' of working the timber. There is more satisfaction in hand planing and scraping to your desired finish than that felt when the timber feeds out the back end of the drum sander!

Drum sanders are great for speed and also for 'difficult' timbers such as anything highly figured. An electric planer/thicknesser will rip the guts out of figured material or at least the risk is high so if it were between these, you'd go the sander. Some hand planes however are also made to deal with difficult and cranky timbers and though care must be taken and skill required, will do an excellent job. Drum sanders are somewhat 'no brainers'. They are a work horse to get you from A to B very quickly.

As you are probably aware, you definitely need a dust extractor on a drum sander. This does make the equation quite expensive. Having said that, the planes you are looking at are not cheap either! They will however hold their value over time being quality tools.

Shit I ramble.

Right thats it, things to consider -

Hand planes: will work and do a good job, even quite quickly however learning curve is steep and stakes are often high. Tearing a chunk from your figured blackwood back at 2.5mm thick is not a pleasant experience, should you have thought otherwise. They are quiet - use anytime! They create lovely shavings not nostril clogging dust. You can precisely control what thickness your results are but getting that thickness evenly across the board takes practice. Veritas make some lovely planes. I'm with Martin - I have the low angle block and it's great, in my opinion, better than the LN of same but again, not for this job. I have tried the Lie-Neilson scraper plane which works beautifully. I'm sure as does the Veritas. Both companies manufacture excellent hand planes and which one I would choose over the other depends on the model itself. As for the smoother, you could go either way and be very happy. Veritas do make low angle versions of several of their planes which are beautiful to use and also slightly wider than standard. In essence, the combo you mention will work fine, as would the reverse combo (with say a Veritas low angle smoother or bevel up smoother) which is the way I'd personally lean. Another option, which I have, is a Terry Gordon smoother (http://www.hntgordon.com.au). These are traditional wooden planes made here in Australia that are of such a design as to be both smoother and scraper in one (by reversing the set-up). They work beautifully on even highly figured hard woods, but don't have the ease of micro-adjustment which puts some people off. The blades are awesome and he does have a newer mechanically adjustable model for those who don't like the hammer technique. Just a thought but highly recommended.

Drum Sander: The Performax sanders are made well and work well but as with all machines, need to be used within their capabilities and also require maintenance. They are not 'thicknessers' but finish sanders and as such, they will only remove a small amount of material at a time. This is mostly what you want but if you try to take too much, the smaller units will stall quickly which frustrates many and causes people to think they are faulty. So taking a 5mm chunk of Indian Rosewood down to 2.5mm can take many passes and some time. They aren't the nosiest machines in the workshop but still cause a racket. Adjusting them should your material be coming out uneven can be a pain in the **** depending on model. Having said all this, I wouldn't be without mine now. There are jobs I still reach for my hand planes for but for the general thicknessing down to size of my plates, I use the sander every time. You can control very well the thickness achieved though I still prefer to finish with scrapers. Note also that many models will not sand down to the thickness we require as they limit this so you do not sand into your conveyor plate or belt. You would need to build a 'sled' to carry your plates.

Oh and I agree again with Martin - go buy some scrapers and practice using them. They are the most useful bits of metal in the workshop!

Hope this helps.

Jeremy.

- J.F. Custom

- Blackwood

- Posts: 779

- Joined: Fri May 01, 2009 9:13 pm

- Location: Brisbane

- Contact:

- matthew

- Blackwood

- Posts: 1192

- Joined: Mon Oct 08, 2007 1:16 pm

- Location: Sydney, Inner West

- Contact:

I thicknessed all the ribs and backs of my double basses with a nice sharp #4 Stanley and careful attention to planing direction. Also thicknessed wooden strips for making purfling the same way. Crossed diagonal strokes are good. I can't stand noisy tools, and dust is my enemy. I have to put up with both, of course, but a minimum puh-leeeease.

-

Pete Brown

- Blackwood

- Posts: 115

- Joined: Tue Dec 09, 2008 1:15 pm

Re: Thicknessing by hand

I know many people prefer to use hand tools wherever possible and I admire those who do. That said, I've come to recognise my own limitations over time and happily make use of my thickness sander to thickness top, back and sides. In fact, I can't think of too many components where I don't use it. Use hand tools if that's your preference, but spend a few moments to consider all the parts a thickness sander can help you fabricate other than those you mention!PHANTOM wrote:it is a shit load of money for something that I will only use to thickness the top, back and sides then will sit there while i build the rest of the guitar

I was and mostly still am, very happy thicknessing with a plane, I have a few most are old English or Japanese ones I’ve picked up over the years so I can’t be much help with brand names. But there are times when a plane is a pain, like my first attempt at thinning down a very pretty almost white set of 6mm thick figured/flamed maple (the Yank maple not our nice easy to work with Queensland stuff). At around 3mm, after much stuffing around and many frustrating jams, I finally succeeded in ripping a chunk right of one back piece and at the same time splitting it along half the length.

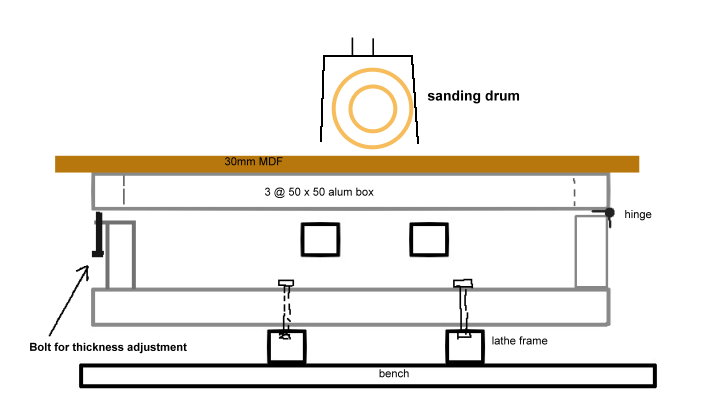

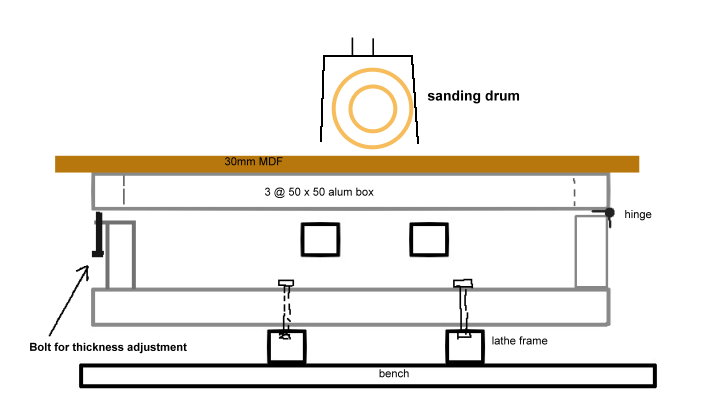

At this point I decided I needed a drum sander for those nasty timbers like burl and flamed maple and not being able to justify the cost for the amount of time I would use it, I decided to build something. My answer was to make a temporary conversion to my old GMC lathe (picked up for $60 at a local auction). For the drum I used the inside cardboard tube from a newspaper roll which is 110mm outside dia with walls 12mm thick, these are solid as and nice and true. I turned down some pine as end caps and screwed and glued them into a 500mm length of the tube. After putting it in the lathe and giving it a quick skim to take off any high spots, I spiral wrapped it with 80 grit cloth backed sanding belt (I had a couple of 100mm wide industrial linisher belts laying around). With the drum part done I made a 1200mm long 500 wide frame which I attached to the lathe frame under the drum. For dust extraction I made a thin ply hood with a couple of clear plastic windows and attached the vacuum cleaner to it.

I don’t have a camera at the moment (someone at the beach decided that they needed it more than I did) so here is a very rough photo shop sketch of what it the cross section looks like. All up it took me about 4 hours to make and was made from stuff I already had in my junk pile so cost me nothing. I’ve recently cut away a couple of areas of the dust hood and made them removable, which gives me access to the drum for all kinds of sanding odd jobs.

While it would be nice if it had a bit more grunt, but it does a good enough job and only takes about 10 min to set up on the lathe, then when I’m done it goes back into the corner and I have my lathe back as a lathe.

Cheers

James

At this point I decided I needed a drum sander for those nasty timbers like burl and flamed maple and not being able to justify the cost for the amount of time I would use it, I decided to build something. My answer was to make a temporary conversion to my old GMC lathe (picked up for $60 at a local auction). For the drum I used the inside cardboard tube from a newspaper roll which is 110mm outside dia with walls 12mm thick, these are solid as and nice and true. I turned down some pine as end caps and screwed and glued them into a 500mm length of the tube. After putting it in the lathe and giving it a quick skim to take off any high spots, I spiral wrapped it with 80 grit cloth backed sanding belt (I had a couple of 100mm wide industrial linisher belts laying around). With the drum part done I made a 1200mm long 500 wide frame which I attached to the lathe frame under the drum. For dust extraction I made a thin ply hood with a couple of clear plastic windows and attached the vacuum cleaner to it.

I don’t have a camera at the moment (someone at the beach decided that they needed it more than I did) so here is a very rough photo shop sketch of what it the cross section looks like. All up it took me about 4 hours to make and was made from stuff I already had in my junk pile so cost me nothing. I’ve recently cut away a couple of areas of the dust hood and made them removable, which gives me access to the drum for all kinds of sanding odd jobs.

While it would be nice if it had a bit more grunt, but it does a good enough job and only takes about 10 min to set up on the lathe, then when I’m done it goes back into the corner and I have my lathe back as a lathe.

Cheers

James

ShopNotes has a nice DIY drumsander. The only issue I had with it is that it isn't wide enough, which is easy enough to fix. The entire thing is built out of MDF with the exception of two maple bearing blocks. It has a crank powered feeding belt that could easily be connected to a rotisserie motor. I've got the plans on my old computer if you're interested.

-

Rick Turner

- Blackwood

- Posts: 311

- Joined: Sun Jan 13, 2008 10:22 am

- Location: Santa Cruz, Ca.

- Contact:

An issue: Are you trying to make a living at instrument building, or are you doing it for your own pleasure and maybe a bit of income to offset costs? If you're trying to actually make a living at lutherie, this is a no-brainer. You'll need a drum or wide belt sander AND adequate dust extractor. Unfortunately, guitarists buy guitars, not your Zen experience of building them, so hand planing is just not cost effective for most pro luthiers. On the other hand, if you're doing this for yourself and don't have to make a decent wage at it, hand planing is a really wonderful activity.

Rick Turner

Guitar Maker, Experimenter, Diviner

www.renaissanceguitars.com

www.d-tar.com

Guitar Maker, Experimenter, Diviner

www.renaissanceguitars.com

www.d-tar.com

- woodrat

- Blackwood

- Posts: 1154

- Joined: Tue Nov 25, 2008 6:31 am

- Location: Hastings River, NSW.

- Contact:

Hi Phantom, another option you may consider especially if you love planes (as I do) is to get one of Terry Gordon's great wooden planes. Interestingly it is both a scraper and a high angle smoother as the beefy 6mm tool steel or optional HSS blade can be used in the normal position for a 60 deg high angle smoother or flipped around to give a 90 degree scraper. It is a tap to adjust wedge plane, but dont let that put you off as the plane is really quite easy to adjust after a bit of practice. It is great on figured woods and leaves a polished finish from a sharp blade. It is a soother so its not really for taking the bulk off but used in conjunction with other planes its great. I have a Gidgee one and a Macassar ebony one. I am not affiliated with HNT Gordon planes I just own a couple of them and find them to be brilliant. Google "HNT Gordon planes Australia"

- sebastiaan56

- Blackwood

- Posts: 1279

- Joined: Sun Oct 28, 2007 5:23 am

- Location: Blue Mountains

-

Paul B

I built my own drum sander. I use it for all sorts of stuff, not just thicknessing backs sides and tops. It's also good for putting that curve in the back of a headstock (*edit: volute is the word I was looking for), thicknessing braces, tapering necks, and truing up rough sawn lumber/fretboards etc.

When I actually find time to build, I use it all the time. Get one and you'll never go back.

When I actually find time to build, I use it all the time. Get one and you'll never go back.

Last edited by Paul B on Thu Jun 18, 2009 1:00 pm, edited 1 time in total.

- woodrat

- Blackwood

- Posts: 1154

- Joined: Tue Nov 25, 2008 6:31 am

- Location: Hastings River, NSW.

- Contact:

Hi Paul B, Could you post a couple of pics of your sander, I have been considering building one as against the large investment of buying one. CheersPaul B wrote:I built my own drum sander. I use it for all sorts of stuff, not just thicknessing backs sides and tops. It's also good for putting that curve in the back of a headstock, thicknessing braces, tapering necks, and truing up rough sawn lumber/fretboards etc.

When I actually find time to build, I use it all the time. Get one and you'll never go back.

John

-

Paul B

I'm with Paul, planes are great and can be used very effectively to thickness plates I use them for lots of other task as well. So to is the Wagner STP a very effective and handy tool. But I use my drum sander for heaps of stuff around the place and l continue to be really surprised how much I turn to it.

Quite frankly I don't know how I got by without my performax 16/32, high figured wood is expensive, and hand planning always carries 'some' element of tear out risk no matter how well a plan is set up. Using a drum sander takes all of the risk out of the equation, it's a tool which has become almost indispensable for me these days and if it were lost today I would replace it tomorrow in a heart beat.

Cheers

Kim

Quite frankly I don't know how I got by without my performax 16/32, high figured wood is expensive, and hand planning always carries 'some' element of tear out risk no matter how well a plan is set up. Using a drum sander takes all of the risk out of the equation, it's a tool which has become almost indispensable for me these days and if it were lost today I would replace it tomorrow in a heart beat.

Cheers

Kim

I've got the Performax 10-20 and I use it nearly every day. Brilliant little machine for most things lutherie. I have access to a 16-32 for those larger tasks, but I'd say that well over 90% of the work I use it for is easily handled by the 10-20.

I also have some HNT Gordon Planes. Simply the best planes I've ever used, bar none. And though you might think that a wooden plane is difficult to adjust, these ones are easier than any steel plane that I've used.

I also have some HNT Gordon Planes. Simply the best planes I've ever used, bar none. And though you might think that a wooden plane is difficult to adjust, these ones are easier than any steel plane that I've used.

-

vandenboom

- Blackwood

- Posts: 414

- Joined: Sun Oct 26, 2008 2:27 pm

- Location: Melbourne (Ringwood), Australia

Like yourself, I couldn't justify a commercial drum sander. But my hand tool skills weren't good enough to do a good job entirely by hand. So I made the following for about $300. 26"wide, 2HP motor, 5" drum (MDF discs on a 3/4" steel bar). Drum is velcro backed. It lets me do things I just couldn't do before, like make my own bindings. You still need the space for it and the dust extractor, but the latter I could justify (aprox $200 for small one).

There are lots of other examples of this on OLF, but happy to provide more info/pics if you want it. Frank

There are lots of other examples of this on OLF, but happy to provide more info/pics if you want it. Frank

Last edited by vandenboom on Thu Jun 18, 2009 7:38 pm, edited 1 time in total.

-

Paul B

Who is online

Users browsing this forum: Google and 29 guests