Stew Mac Bending iron

Stew Mac Bending iron

Hi all,

I am new to this forum and guitar building. Looking at purchasing a side bender and have heard some goods things about the Stew Mac bending iron. Would like to hear others experience with these or some alternatives.

Thanks in advance,

I am new to this forum and guitar building. Looking at purchasing a side bender and have heard some goods things about the Stew Mac bending iron. Would like to hear others experience with these or some alternatives.

Thanks in advance,

Klufty

Welcome to the forum Klufty,

Both the LMI and Stewmac bending irons are good for general bending. Ive got the LMI version in my shop and its done good service. If you shop around there are cheaper equivalents on ebay etc. Im told some of these irons are essentially from same supplier as the onees that LMI and Stewmac supply. Others who are using these irons will no doubt chime in and add comments accordingly.

Cheers Martin

Both the LMI and Stewmac bending irons are good for general bending. Ive got the LMI version in my shop and its done good service. If you shop around there are cheaper equivalents on ebay etc. Im told some of these irons are essentially from same supplier as the onees that LMI and Stewmac supply. Others who are using these irons will no doubt chime in and add comments accordingly.

Cheers Martin

Go for a 14" minimum...if youre planning on doing any resawing then aim a bit bigger.

Ive got a Carbatec 14" bandie that does most of what I need it to do. I did upgrade to the better bearing based guides on the thing. If I was buying again Id probablly go for a Jet over a Carbatec mainly because service from Jet agents seems to be generally better than that from Carbatec of late.

Ive got a Carbatec 14" bandie that does most of what I need it to do. I did upgrade to the better bearing based guides on the thing. If I was buying again Id probablly go for a Jet over a Carbatec mainly because service from Jet agents seems to be generally better than that from Carbatec of late.

- J.F. Custom

- Blackwood

- Posts: 779

- Joined: Fri May 01, 2009 9:13 pm

- Location: Brisbane

- Contact:

Hi Klufty and welcome.

Firstly - I've got the Stew-Mac bending iron which I 'upgraded' to from the blow torch hot pipe method. The hot pipe works fine and you can't beat it for price - I just wanted some more repetitive control in the heat, hence the upgrade. I too believe Ibex manufacture for both Stew Mac and LMI. The only reason I went for the Stew-Mac in the end is that they slightly modify theirs with the addition of a tapped thread in the end. This allows use of their smaller extension for very tight bends in mando's or violins etc.

With regard to your second question, 10" is not enough. At a pinch it could do for a starter but you will VERY quickly outgrow it and find its limitations. Therefore the money spent would somewhat be money wasted. Better saving it and putting it toward a 14" minimum. These will do most luthiery jobs but, as mentioned, will struggle to re-saw. I had and used a 14" model for years but had to continually get my larger stock resawn by others which was an expensive and 'uncontrolled' solution. If you don't plan to re-saw, as in you are prepared to buy back and side sets etc, 14" is enough. I upgraded some time back to a 17" Carba-Tec model so I could do 95% of jobs myself and have never looked back.

Jet and Carba-Tec make good machines, at least, for the most part. Both have machines manufactured in Taiwan and China, as most companies/brands do now. The difference in quality and price is which factory they have produce the machine and what specs they chose or have upgraded. I have been to many of the factories in China and Taiwan that produce Jet and Carba-Tec - some factories produce both and others such as Powermatic too. I have fair knowledge and information on this type of thing. If you have any questions or have any model in particular in mind, fire me a message. Same goes to all on the forum.

Good luck,

Jeremy.

Firstly - I've got the Stew-Mac bending iron which I 'upgraded' to from the blow torch hot pipe method. The hot pipe works fine and you can't beat it for price - I just wanted some more repetitive control in the heat, hence the upgrade. I too believe Ibex manufacture for both Stew Mac and LMI. The only reason I went for the Stew-Mac in the end is that they slightly modify theirs with the addition of a tapped thread in the end. This allows use of their smaller extension for very tight bends in mando's or violins etc.

With regard to your second question, 10" is not enough. At a pinch it could do for a starter but you will VERY quickly outgrow it and find its limitations. Therefore the money spent would somewhat be money wasted. Better saving it and putting it toward a 14" minimum. These will do most luthiery jobs but, as mentioned, will struggle to re-saw. I had and used a 14" model for years but had to continually get my larger stock resawn by others which was an expensive and 'uncontrolled' solution. If you don't plan to re-saw, as in you are prepared to buy back and side sets etc, 14" is enough. I upgraded some time back to a 17" Carba-Tec model so I could do 95% of jobs myself and have never looked back.

Jet and Carba-Tec make good machines, at least, for the most part. Both have machines manufactured in Taiwan and China, as most companies/brands do now. The difference in quality and price is which factory they have produce the machine and what specs they chose or have upgraded. I have been to many of the factories in China and Taiwan that produce Jet and Carba-Tec - some factories produce both and others such as Powermatic too. I have fair knowledge and information on this type of thing. If you have any questions or have any model in particular in mind, fire me a message. Same goes to all on the forum.

Good luck,

Jeremy.

- graham mcdonald

- Blackwood

- Posts: 473

- Joined: Thu Oct 25, 2007 11:57 am

- Location: Canberra

- Contact:

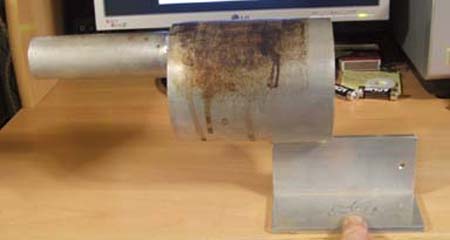

I use a couple of lengths of brass pipe 65mm and 40mm (roughly) in diameter with a propane torch. One worthwhile addition is mostly filling in what would be the non-torch end with a bit of brass sheet cut into a cross shape and pop riveted onto the end.

The pipes are hot enough when water sprayed on bounces straight off. If it sits there and bubbles the pipe isn't hot enough and there is a good chance your side/binding will break

cheers

graham

The pipes are hot enough when water sprayed on bounces straight off. If it sits there and bubbles the pipe isn't hot enough and there is a good chance your side/binding will break

cheers

graham

Graham McDonald

http://www.mcdonaldstrings.com

http://www.mcdonaldstrings.com

True that the Jet and Carbatec machines come out of the same factory but level of QC during manufacture can vary with the client. As alluded to in my earlier post, service from Carbatec pre and post sale is not quite as good IMO as that offered by Jet agents.J.F. Custom wrote:

Jet and Carba-Tec make good machines, at least, for the most part. Both have machines manufactured in Taiwan and China, as most companies/brands do now. The difference in quality and price is which factory they have produce the machine and what specs they chose or have upgraded. I have been to many of the factories in China and Taiwan that produce Jet and Carba-Tec - some factories produce both and others such as Powermatic too. I have fair knowledge and information on this type of thing. If you have any questions or have any model in particular in mind, fire me a message. Same goes to all on the forum.

Good luck,

Jeremy.

- J.F. Custom

- Blackwood

- Posts: 779

- Joined: Fri May 01, 2009 9:13 pm

- Location: Brisbane

- Contact:

Just for clarification of my statement - no, not all Jet and Carba-Tec machines come from the same factory/s. Some cross over while some are simply very similar machines from different factories - copies if you like.kiwigeo wrote:True that the Jet and Carbatec machines come out of the same factory but level of QC during manufacture can vary with the client. As alluded to in my earlier post, service from Carbatec pre and post sale is not quite as good IMO as that offered by Jet agents.

OK, here is some more info for you all.

Yes, quality control is one factor, but I disagree with the above statement (sorry Martin!).

This really does come down to actual manufacturer more so than brands within the one manufacturer. Brands within the one manufacturer differ more in the selected options or requested modifications by the relevant company.

Some machines of both brands are stock standard models made by a relevant manufacturer.

Sometimes one brand over another is given exclusive license to sell the product due to a deal struck that proves too good to refuse. Sometimes entire manufacturers are sown up to one company, preventing other companies access regardless of machine type. I don't mean factories actually owned by one company or another either, but third parties.

Other machines are simply 'up-specced'. That is the base model has several 'optional' additions. Different companies select different options.

Yet other machines will have minor modifications made either A - to improve the models performance and reliability; or B - to make a 'point of difference' to the competitors product that is then 'licensed' to that company. An example may be a different plastic molding on a given part of a machine to 'look the part' when the guts are the same.

Finally some machines are entirely researched and designed by a specific company and then made to those exacting specifications. These are for the most part only available to the original designing company.

So there it is in a nutshell.

Jet are a very large US company that have had many years experience. They also have a much larger market than just Australia and as a result, have more money to put into some of the finer details. They have a large part to play in making Taiwanese machinery what it is today, as they established business there so many years ago. They deserve the reputation they have, again, for the most part.

Carba-Tec is a much smaller company here in Australia and while it would seem to us Aussies or Kiwis for that matter, that they are very large, they are nothing on Jet in this respect and US will likely not have heard of them. They too deserve their reputation, again, for the most part.

To a certain extent, you get what you pay for. Knowing what I do I can say this of both companies; some machines are well priced for what they are, others are well over priced or differences are overstated and overblown.

I think if you were to spend wisely with either company, you would be happy with your purchases - they are good machines and we have to be thankful they are available to us! Where would I be without my bandsaw??

As for service, I guess that is a matter of opinion and who you happen to deal with both personally and store to store, state to state. Each will have their own experiences and I don't want to comment on that. Theoretically both should be providing good service, pre or post to any customer. Unfortunately this is not always the case - Martin appears to be case in point! What I am saying is on a purely machine to machine basis, both should prove to be a good purchase (depending on exact model!!) so perhaps if they are comparable, it does come down to the service you individually receive from each...

Jeepers... That was a long winded 'clarification' ramble.

Sorry, but I hope the info is of use to some!

Jeremy.

Jeremys clarification is proved by the fact that Hare and Forbes carry the same machines as Carba-Tec and sell them at a better price . They have the absolute best after sales service and carry the spare parts to back it up. Sound like a plug? No, just a very happy customer who has been on the end of some good treatment. They have branches in Sydney,Brisbane,Melbourne and Perth. and I find it cheaper to hop in the ute and go to Sydney than take the 15 minute trip to the local Carba -tec dealer.

Cheers Chopper

Cheers Chopper

side bending

Hi Klufty,

I am on my 3rd guitar and don't have a lot of money or room, so for bending I use a 75mm stainless exhaust pipe offcut kindly donated by "The Man Who Owns The Store" and heat it with a gas torch attached to my barbie bottle. It cost me about $60 for the gas torch kit and adaptor and I figure I shouldn't run out of gas in the middle of a side this way. I wrapped a piece of teflon sheet for barbies and ovens etc around the pipe which makes for smoother, cleaner bending and so far have had great success with Tas Blackwood and WA Sheoak sides and binding. I have a digital laser type thermometer but find as long as it hisses and sizzles and you don't stand still too long it all works fine. I also just ball up some Aluminium foil and shove it in the end that points at the weeding tackle to save accidents and help keep the heat in.

Archie.

I am on my 3rd guitar and don't have a lot of money or room, so for bending I use a 75mm stainless exhaust pipe offcut kindly donated by "The Man Who Owns The Store" and heat it with a gas torch attached to my barbie bottle. It cost me about $60 for the gas torch kit and adaptor and I figure I shouldn't run out of gas in the middle of a side this way. I wrapped a piece of teflon sheet for barbies and ovens etc around the pipe which makes for smoother, cleaner bending and so far have had great success with Tas Blackwood and WA Sheoak sides and binding. I have a digital laser type thermometer but find as long as it hisses and sizzles and you don't stand still too long it all works fine. I also just ball up some Aluminium foil and shove it in the end that points at the weeding tackle to save accidents and help keep the heat in.

Archie.

- sebastiaan56

- Blackwood

- Posts: 1279

- Joined: Sun Oct 28, 2007 5:23 am

- Location: Blue Mountains

-

vandenboom

- Blackwood

- Posts: 414

- Joined: Sun Oct 26, 2008 2:27 pm

- Location: Melbourne (Ringwood), Australia

I used the blowtorch in the pipe for my first, but found it unpleasant to work around.

Since then, I bought a pencil shaped heating element from Hotco in Cheltenham (Melb) - cost about $60.

I got a short length of 2" copper pipe and distorted its shape to get different different radii. I fill the pipe with sand - good heat conducter apparently. I was lucky to get a simply regulator for nix from a mate, which kept the cost down. And I just the use "drops bouncing off the pipe" as my temp guage.

Frank

Since then, I bought a pencil shaped heating element from Hotco in Cheltenham (Melb) - cost about $60.

I got a short length of 2" copper pipe and distorted its shape to get different different radii. I fill the pipe with sand - good heat conducter apparently. I was lucky to get a simply regulator for nix from a mate, which kept the cost down. And I just the use "drops bouncing off the pipe" as my temp guage.

Frank

- sebastiaan56

- Blackwood

- Posts: 1279

- Joined: Sun Oct 28, 2007 5:23 am

- Location: Blue Mountains

Here is another take on the bending iron device. Go to the bottom of the thread http://mimf.com/cgi-bin/[email protected] ... 2cb6a343/0

A 250W bulb is a lot, I dont know where to get them here in Aus

A 250W bulb is a lot, I dont know where to get them here in Aus

make mine fifths........

-

Corky Long

- Wandoo

- Posts: 14

- Joined: Wed Apr 22, 2009 1:43 am

- Location: Mount Kisco, NY

Si, I've also used both. My Stewmac electric bending iron burned out on the third guitar - I know I can replace the heating element, but am too lazy at this point.

As for the torch method - well, it's pretty much idiot proof, as long as you don't have any open solvents, piles of sawdust, or hair which get close to the bender. I'm not knocking it - I like the torch method best for controlling heat, etc. I just am pretty careful to have a bucket of water and a fire extinguisher handy.

As for the torch method - well, it's pretty much idiot proof, as long as you don't have any open solvents, piles of sawdust, or hair which get close to the bender. I'm not knocking it - I like the torch method best for controlling heat, etc. I just am pretty careful to have a bucket of water and a fire extinguisher handy.

Who is online

Users browsing this forum: No registered users and 56 guests